COMPUTER NUMERICAL CONTROL MANUFACTURING (CNC)

Know more about Our CNC Machines

Watch Video Here

TECHNICAL DETAILS

INTRODUCTION

Every Engineering industry uses various machine tools….. (both conventional and automatic) like Lathe, Milling machines, Drilling machines, Grinding machines etc… to produce different parts. In present days, the industries are more and more concentrating on automatic machines in place of conventional machines.

TECHNICAL DETAILS

MACHINE TOOL

The machine tool is a processing machine, that produce different parts from point of view of shape accuracy, productivity and other conditions, using an specific technological process. There are two categories Machine Tools for metal removing Machine Tools for metal forming

TECHNICAL DETAILS

CONVENTIONAL MACHINE TOOL

The machine tool that is operated by an operator with his hands is called a Conventional machine. The required movements of different slides are obtained by turning the hand wheel attached to the screw rod. Only the Spindle is rotated by an electrical motor.

TECHNICAL DETAILS

AUTOMATIC MACHINE TOOL

Automatic machine tools are called CNC Machines.

What is CNC?

CNC is Computer Numerical Control.

In CNC machines all the operations are controlled automatically. To carry out all these automatic operations Mechanical and Electrical systems are married perfectly to get desired results.

TECHNICAL DETAILS

CONVENTIONAL MACHINE TOOL ARE:

. Less expensive

. Difficult to produce complicated parts

. Less accurate

Takes more time to produce parts

. Operator skills level is more important

TECHNICAL DETAILS

AUTOMATIC MACHINE TOOL:

ELECTRICAL SYSTEM:

Electrical system of a CNC machine consists of:

. CNC System

. Feed back system

. Control Cabinet

. Transformer

TECHNICAL DETAILS

CNC MACHINES ARE:

. Capable of machining complex parts

. Highly accurate

. Highly productive – Faster Machining

. Suitable for batch production

. Used without stopping for tool loading

. All the operations are done automatically – thus human errors are minimized.

TECHNICAL DETAILS

In CNC machines:

. All the basic functions of the machine are done through NC & PLC controls.

. Machining of components is done by feeding a set of instructions to the machine through CNC. These set of instructions are called CNC Part Program.

.The CNC part program can be prepared either on the Screen or in a outside Computer. Then the outside prepared program can be fed to the machine.

ABOUT OUR MACHINES

1. CNC TURNING CENTER, MODEL VX 165

2. CNC TURNING CENTER, MODEL LX 200 SUPER

3. CNC VERTICAL MACHINING CENTER, MODEL V 645

CNC TURNING CENTER MODEL VX 165

Our Turning Centers VX 165 and LX 200 Super are two axes CNC machines with Slant Bed Configuration machines. This configuration machines are more rigid and accurate compared to Flat Bed machines. Also chip disposal and access to the component and tool turret is much better in this configuration.

VX165

LX200

VX 165

1. Job size that can be machined: Dia 165 of 300 mm long.

2. Job size that can be machined: Dia 250 of 200 mm long.

3. Operations : Turning, Facing, Grooving, Boring, Reaming, Thread cutting, Knurling, Chamfering

LX 200 SUPER

1. Job size that can be machined: Dia 200 of 500 mm long.

2. Job size that can be machined: Dia 300 of 300 mm long.

3. Operations : Turning, Facing, Grooving, Boring, Reaming, Thread cutting, Knurling, Chamfering.

ABOUT OUR MACHINES

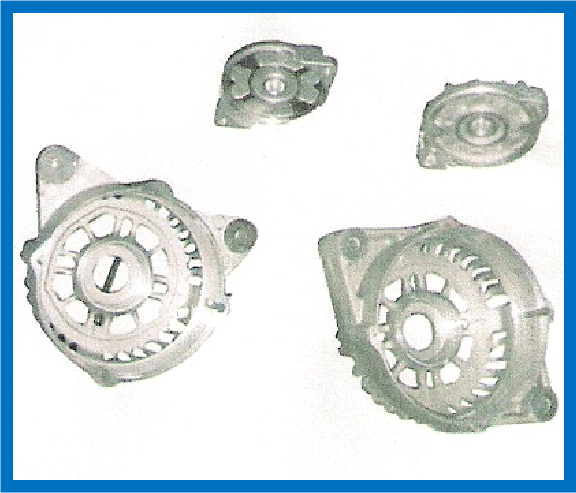

CNC Turning Centers are used to produce Round and Cylindrical parts.

You can use our VX 165 and LX 200 for producing components as shown in the pictures.

APPLICATION FOR LX 200 SUPER

We can produce parts for Automobile industries, Aviation industries, Power generation industries, Construction machinery industries , Beverage industries, and other General engineering industries.

VERTICAL MACHINING CENTER,

MODEL V 645

MODEL V 645

Our VMC V 645 is a 3 axis Fixed Column Configuration machine. This configuration machine is more rigid and accurate compared to moving column machines.

MACHINING CAPACITY : V 645

1. Max Job size that can be machined: 700mm x 450mm x 450mm with max weight of 400kg.

2. Operations : Milling, Drilling, Boring, Reaming, Tapping, Thread Cutting, 3D machining.

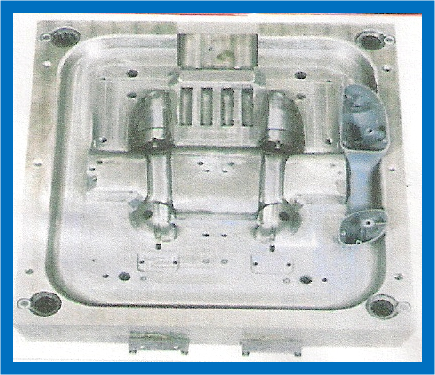

USE OF V 645

VMC’s are used to produce Prismatic parts. We can use our V645 machine for producing components such as displayed in the pictures.

APPLICATION FOR V 645

We can produce parts for Automobile industries, Aviation industries, Power generation industries, Die mould industries, Construction machinery industries , Beverage industries and other General engineering industries.

STANFREY AND CNC

Latest technology.

We can produce complex and intricate parts quickly and accurately.

Increase productivity and improve the quality of the finished product.

Best customer and after sales service.

CONTACT US

-

ADDRESS

2 Agnes Adeniran Street, U Turn Abule-Egba, Abeokuta Road, Agege, Lagos

-

CALL US TODAY

Tel: 017347752

Phone: +234 803 669 8002 -

EMAIL US

info@stanfrey.org

SEND US A

MESSAGE

MESSAGE

MESSAGE

HERE

FIND US ON THE MAP